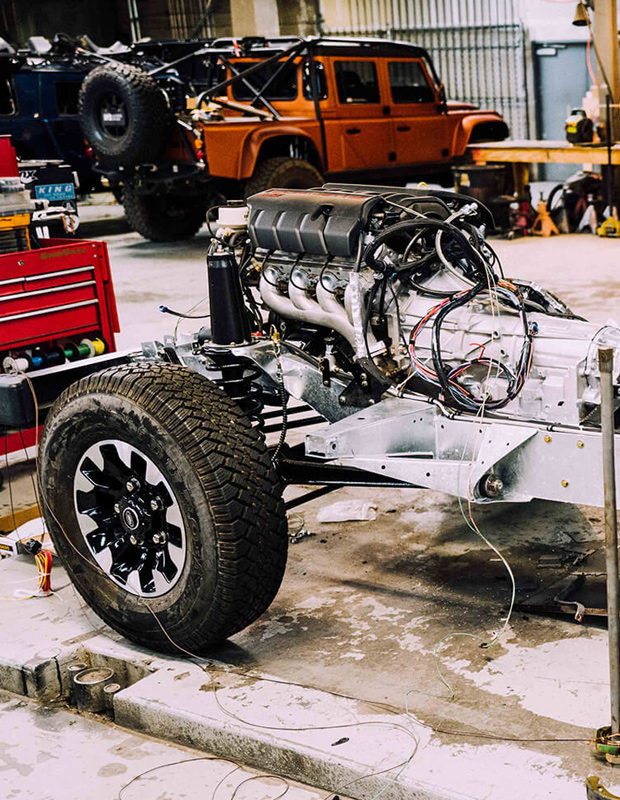

Process

Our frame-up restoration of the Land Rover Defender is a painstaking process that leaves no part untouched. It’s obsessive. It’s compulsive. But the end result is worthy of the automotive icon.

Craftsmanship

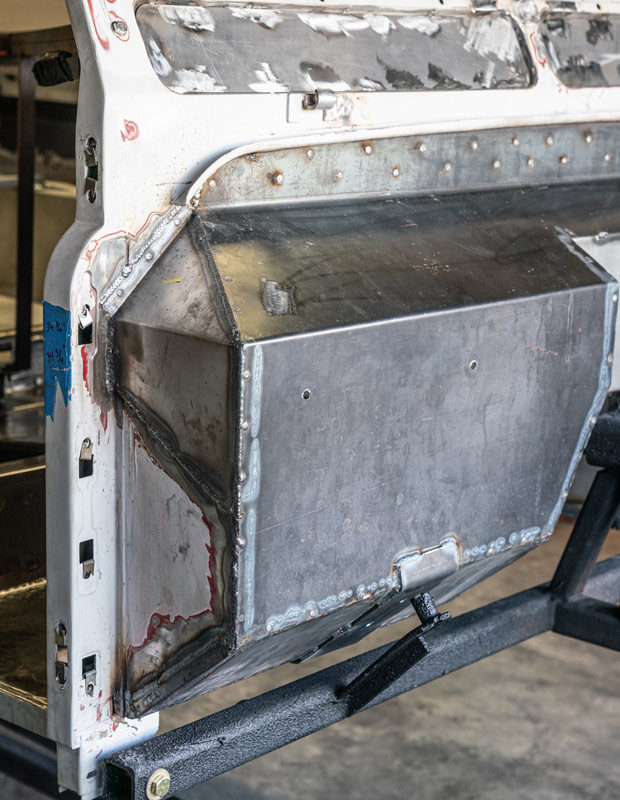

When reworking a beloved icon, the stakes are understandably high. Character, class and a cult-like following define these veteran trucks and any conversion had better be spot on. It’s the stakes that keep us striving, even obsessing, for perfection. We aren’t just restoring Defenders; we address any and all of the original’s shortcomings with a balanced blend of custom fabrication and meticulous re-engineering then bring the comfort and performance up to today’s standards.

Full Marks

They aren’t just slapping a new coat of paint and some accessories on these trucks, but making them straighter, better sealed, more powerful, and most importantly, more reliable than ever before.